New extended producer responsibility for packaging laws are changing the way states and provinces design or redesign recycling systems.

Numerous new MRF projects have received a funding boost to help comply with stricter recycling and recycled content standards across the U.S. and Canada. Here’s a look at some recent MRF project announcements.

Have you heard of other recycling facility news we should know about? Send us an email at waste.dive.editors@industrydive.com.

The Recycling Partnership offers $4.25M grant to FCC Environmental to boost film recycling

FCC Environmental Services in Houston, Texas, received a $4.25 million grant from The Recycling Partnership to improve film and flexible packaging recycling at the facility. The funding is the largest single grant the Partnership has given to an individual MRF.

The FCC grant is supported by PepsiCo, Kraft Heinz, and the Film and Flexibles Recycling Coalition.

FCC will use the grant to retrofit its Houston MRF to recover plastic film and meet market specifications for the material, according to a news release.

The new design adds Tomra optical sorters that separate film from paper, along with other key equipment and conveyors meant to address contamination. FCC also plans to gain new data and insight during the process that it could apply to scaling film and flexibles recycling in other places around the country, said John Rabon, vice president of Recycling at FCC, in a statement.

Plastic film and flexible packaging are used for many applications, but aren’t commonly accepted in curbside bins, he said.

The Recycling Partnership aims to work with packaging producers and the broader recycling industry to help advance film recycling infrastructure and markets for the material through its Film & Flexibles Recycling Coalition, which it started in 2020 . That coalition has offered about $11 million across 25 film and flexible projects since then, the Partnership said.

Major brands are investing in flexible packaging recycling initiatives in part because of stricter recycling and recycled content regulations under new extended producer responsibility laws, particularly California’s SB 54.

Companies that can’t meet the newer, steeper recycling rates for film and flexible packaging may face steep fines or potential product bans, said Kate Davenport, chief impact officer at The Recycling Partnership.

“To meet these mandates effectively, investment now in the supply chain to turn FFP into new products is critical,” she said in a statement.

Film and flexible packaging makes up 34% of the total U.S. plastics packaging industry, the Partnership said, but has an “incredibly low” annual recycling rate, in part because it gets caught in recycling equipment and can contaminate other streams such as paper. It also has a high processing cost and limited end market demand, the Partnership said.

Bruin Waste, BHS to open new MRF in Grand Junction, Colorado

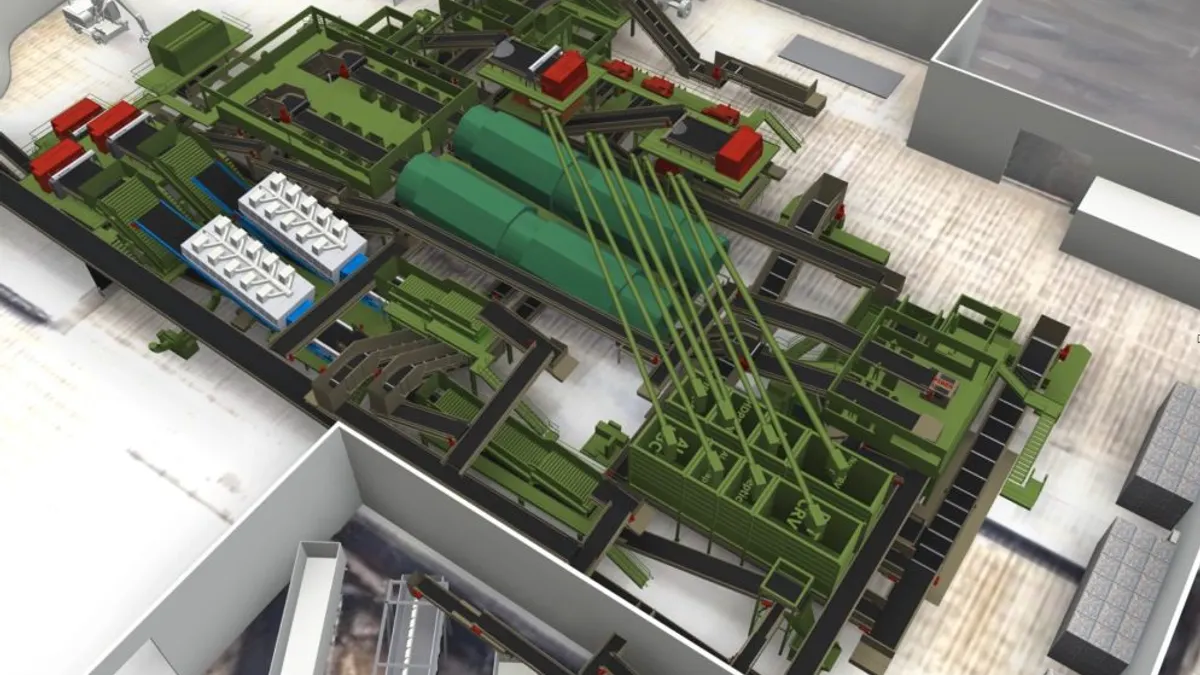

Bruin Waste will operate a new single-stream MRF in Grand Junction, Colorado. This will be the only automated MRF in Colorado’s Western Slope region, according to a news release. The facility, designed and built by Bulk Handling Systems, is set to open in June 2026.

The project is part of the city of Grand Junction’s goal to increase recycling access and capacity in the region. The city announced last week that it received a $9.8 million grant from the state’s Circular Communities Enterprise to help further those goals.

Jeffrey Kendall, CEO of Bruin Waste, said in a statement that the new MRF will “dramatically” increase local recycling and processing capabilities. The MRF will also help the region prepare for Colorado’s new extended producer responsibility for packaging law, he said, which was partly designed to significantly overhaul recycling requirements for rural areas.

“We believe this project represents an important step forward in bringing the most advanced recycling technologies and automation to smaller communities where currently none exist,” he said.

The 12 ton-per-hour MRF will include multiple AI-powered “detection points” using BHS’ AI-powered air separators, optical sorters and real-time monitoring platform. It will also install debris roll screens and polishing screens meant to reduce instances of materials wrapping around equipment, BHS said.

BHS to design and build new equipment for Sunnyvale, California facility

BHS was awarded a $34.5 million contract to design, manufacture and install a variety of equipment at the Sunnyvale Materials Recovery and Transfer (SMaRT) Station in Sunnyvale, California. The design is meant to streamline the facility’s operations with a single, integrated system for both MSW and recycling, BHS said.

BHS will replace the facility’s existing equipment with a high-efficiency processing line capable of handling 100 tons per hour of MSW and 20 tons per hour of source-separated recyclables, according to a news release. The system is also expected to recover and divert over 75% of inbound MSW organic material for composting. California’s organics law, SB 1583, requires specific organics diversion metrics.

The project includes installation of new AI-powered air separators, optical sorters, OCC separators and drum separators, BHS said.

Metaspectral grants aims to improve film recycling in Canada

Financial information is in Canadian dollars.

Metaspectral, a Canadian AI-powered recycling technology company, has received $850,000 from Environment and Climate Change Canada as well as CleanBC. The company is developing technology meant to more easily sort multilayer packaging at recycling facilities.

“Plastic film is difficult to sort efficiently, which has historically led to contamination of post-consumer recycled materials, significantly reducing their utility and market value,” said Francis Doumet, CEO and co-founder of Metaspectral, in a statement.

The company’s cameras use spectral signatures to detect the molecular makeup of material on a conveyor belt. Metaspectral then uses AI to identify and separate materials in real time on recycling facilities’ conveyor belts.

Metaspectral’s work is driven in part to reduce ocean plastic pollution in Canada as well as improve the country’s overall recycling systems, Doumet said. More provinces are adopting or upgrading extended producer responsibility programs and adopting stricter recycled content requirements.

The new grant follows Metaspectral’s initial Phase 1 grant of $150,000, awarded in April 2024 as part of the Canadian Plastics Innovation Challenge. That funding was meant to support projects that improve collection and sorting of plastic film and flexible packaging.

Metaspectral also previously received $419,000 in funding from the CleanBC Plastics Action Fund to use its technology to differentiate between homopolymer and copolymer plastics, such as HDPE.

Merlin Plastics, a major Canadian recycling company, currently uses Metaspectral’s sorting technology.

This story first appeared in the Waste Dive: Recycling newsletter. Sign up for the weekly emails here.