AI-enabled tech startup Visia sees itself as being in the problem-solving business, not just the AI business.

The company, which builds custom systems for recyclers in the MRF, C&D and electronics recycling space, counts companies such as Rumpke Waste and Recycling, Casella Waste Systems, LRS and Coastal Waste among its clients. Visia got its start a few years ago by offering technologies meant to help these facilities optimize equipment and operations, and it’s best known for its X-ray sensors, which can be programmed to detect certain materials or hazards such as batteries, particularly on crowded belts. It also provides other cameras, sensors and custom dashboard offerings.

“We always ask, ‘What are the problems you’re trying to solve for? And then we'll make a recommendation. We’re not just trying to sell you a sensor,” said Aoife Duna, Visia’s head of revenue.

After raising $6.4 million in seed financing last year, the company has been focused on expanding its range of technology offerings.

But Visia is also expanding its services offering artificial intelligence-enabled camera equipment meant to help companies automate waste audit processes and material composition reports, or improve sorting equipment or throughput strategies. It also offers custom dashboards for clients to track and monitor their custom needs.

“We've had pretty significant growth in the last year,” Duna said, noting Visia went from installing its tech at about a dozen facilities to over 30. Each installation is significantly different from company to company, she said.

Visia aims to differentiate itself from other AI-powered tech companies by working across multiple recycling verticals, such as MRFs, scrap and e-scrap recycling facilities and C&D recyclers, she said. That allows Visia to collect a wider AI dataset, which Duna said helps accelerate how much the tech improves over time.

Visia also aims to offer technologies that can work hand-in-hand with facilities’ existing robotics or AI-enabled sorting systems. Visia’s tech is meant to identify hazards that are buried under other materials on fast-moving belts, something Duna said is harder for some robotics technologies to master.

“Where we started was asking, ‘Can we characterize the material that's coming through [facilities] as a way of replacing manual audits?’ But it became so clear that a lot of the problems lie under the surface, and those are things that people are looking to detect,” she said.

Customizing for operations improvements

Casella Waste Systems has installed Visia technology in six of its MRFs, each with up to six or seven cameras per location.

The technology has been instrumental in tracking how equipment is performing and gaining insight into what kinds of materials are moving through each facility, said Lizzy Elles, Casella’s operations initiatives manager. The cameras are easily movable, which Elles said is ideal for troubleshooting or “adding another data point” to decide on key equipment or operations changes. “It’s a tool that’s very nimble and capital-light,” she said.

Visia can create custom dashboards for its customers, a feature Elles said helps workers visually access waste streams and easily pull up information that allows them to conduct quality control assessments and troubleshoot contamination problems, among other applications.

Casella has invested in key automation upgrades over the last few years, and the Visia equipment has helped work alongside those other infrastructure improvements, she said.

“We've really been able to utilize it very strongly to identify places where we may need to put some investment into our systems,” she said.

Technology for hazard detection

Battery fires have long plagued the recycling industry, and Visia has increasingly been working with companies on how to use its range of technologies to help prevent future fires, Duna said.

Rumpke Waste & Recycling has been vocal about the installation of its Visia X-ray system on the pre-sort line at its Cincinnati MRF. That facility burned down several years ago, and batteries were a suspected cause, said Jeff Snyder, senior vice president of recycling and sustainability, during a fire prevention presentation in May during WasteExpo in Las Vegas.

Snyder estimated the X-ray system identifies more than 100 hazards a day, a significant number considering it’s installed on one of the facility’s two presort lines. “It’s a 50-ton-an-hour facility, and we have this to monitor about 25 tons of that material,” he said. The technology uses a laser pointer to indicate where the battery appears on the line, and workers then physically pull it off, he said.

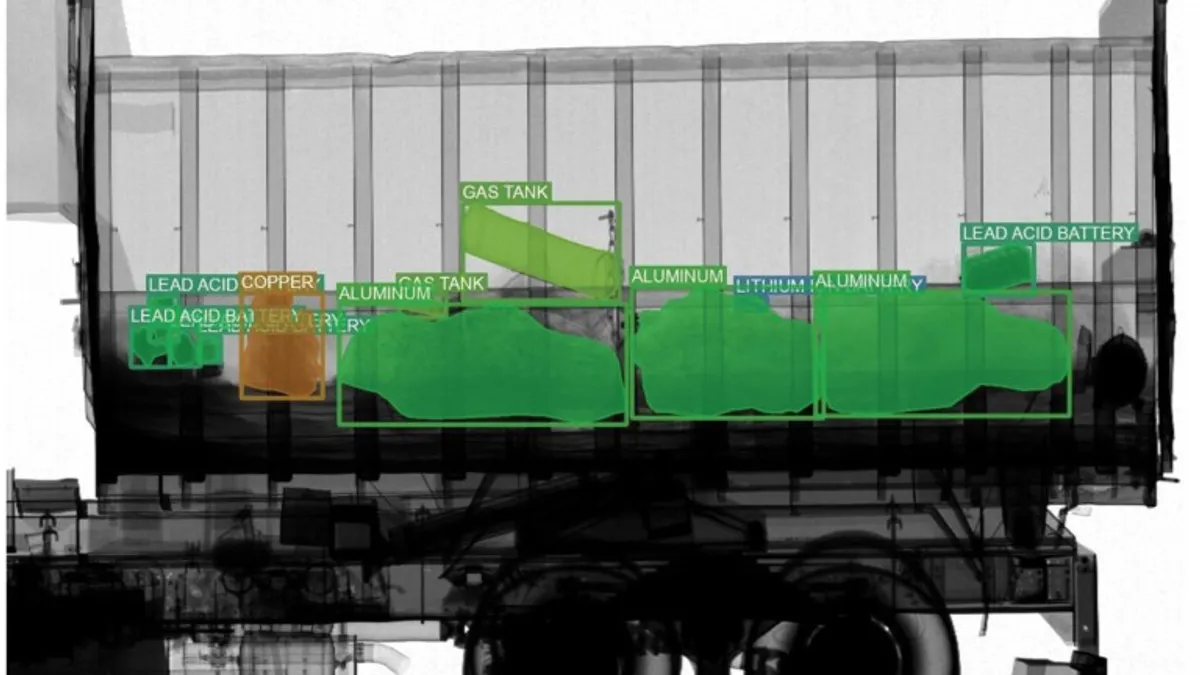

The technology can see through layers of densely packed material and identify the batteries through an item’s atomic density, which Duna said allows companies to more precisely customize what they’re looking for. “We can distinguish between a lithium-ion battery and an alkaline battery or a lead acid,” she said. “Some customers want to have that high level of detail. They may not care about the lead acid, but care about lithium-ion. We also work with battery recyclers who need to have a very thorough breakdown of the chemical compositions.”

Visia recently rolled out a cargo X-ray technology meant to help recyclers price inbound materials by scanning a full truck bed before the material inside is further sorted, she said. “Not only does it proactively identify hazards, but we can distinguish between materials: What's ferrous versus nonferrous versus dirt.”

This story first appeared in the Waste Dive: Recycling newsletter. Sign up for the weekly emails here.